Established in the year 1990 with a capacity of 60 MTPD it has now been extended to 800 MTPD with two separate plants spread over 18 acres of land. The company caters to various large and small bakeries, restaurants and also manufactures Pillsbury Chakki Fresh Atta for General Mills.

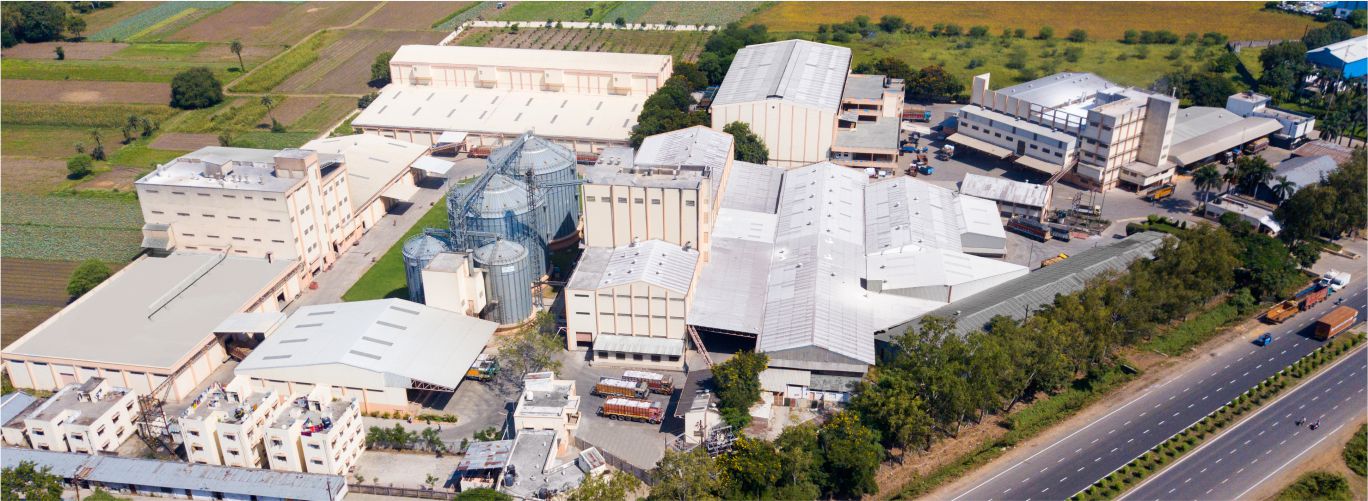

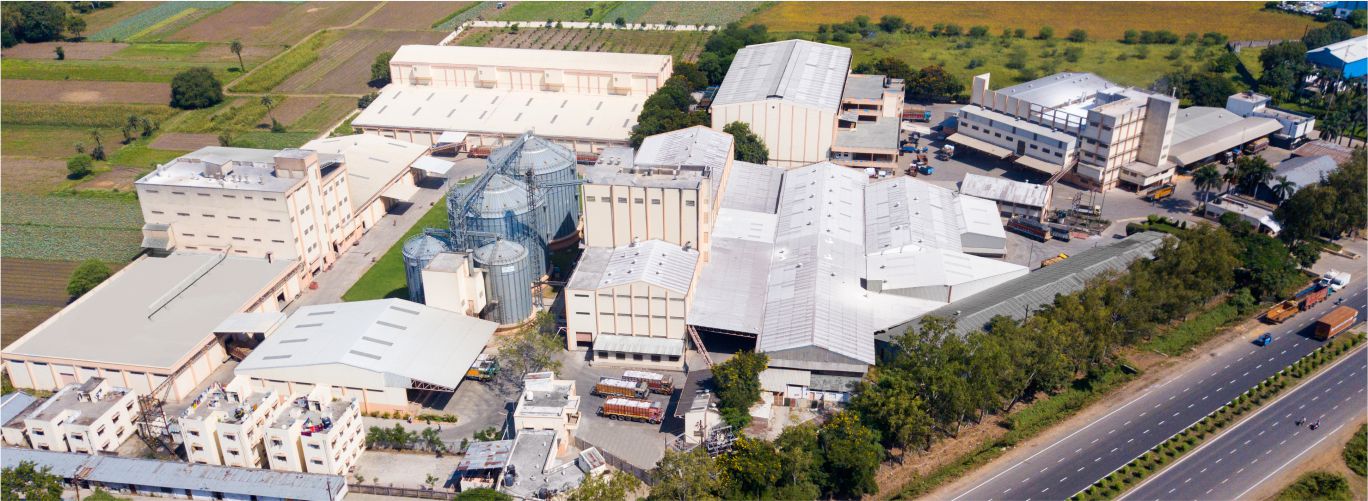

With a production capacity of 800 MTPD, the Nimrani plant is known to have the highest grinding capacity in India, under single roof. The plant is situated 100 kms from Indore on NH-3 towards Mumbai and houses state-of-the-art infrastructure and machineries. The plant specializes in catering to various Institutional clients for their customized requirements.

To cater the constantly rising demand for consumer pack in Mumbai, we took over a flour mill located in Rabale, Vashi in the year 2012 and upgraded with total grinding capacity of 150 MTPD of Chakki atta which is 100 percent sold in retail packs.

Incorporated in the year 2016 with a capacity of 250 MTPD of Chakki atta to cater to the Northern region of the country, it then expanded its capacity with additional 300 MTPD of Wheat flour in the year 2019.

Expanding its horizon towards Eastern India, company expanded its operation by adding a new plant in Chhattisgarh state in the year 2019 with a total grinding capacity of 300 MTPD of Wheat flour and Chakki atta.

Taking a step towards achieving Group’s vision , company established a green filed project in Bengaluru, Karnataka to spread in the Southern market . The unit was set up in the year 2018 with a total grinding capacity of 300 MTPD of Wheat flour and Chakki atta.

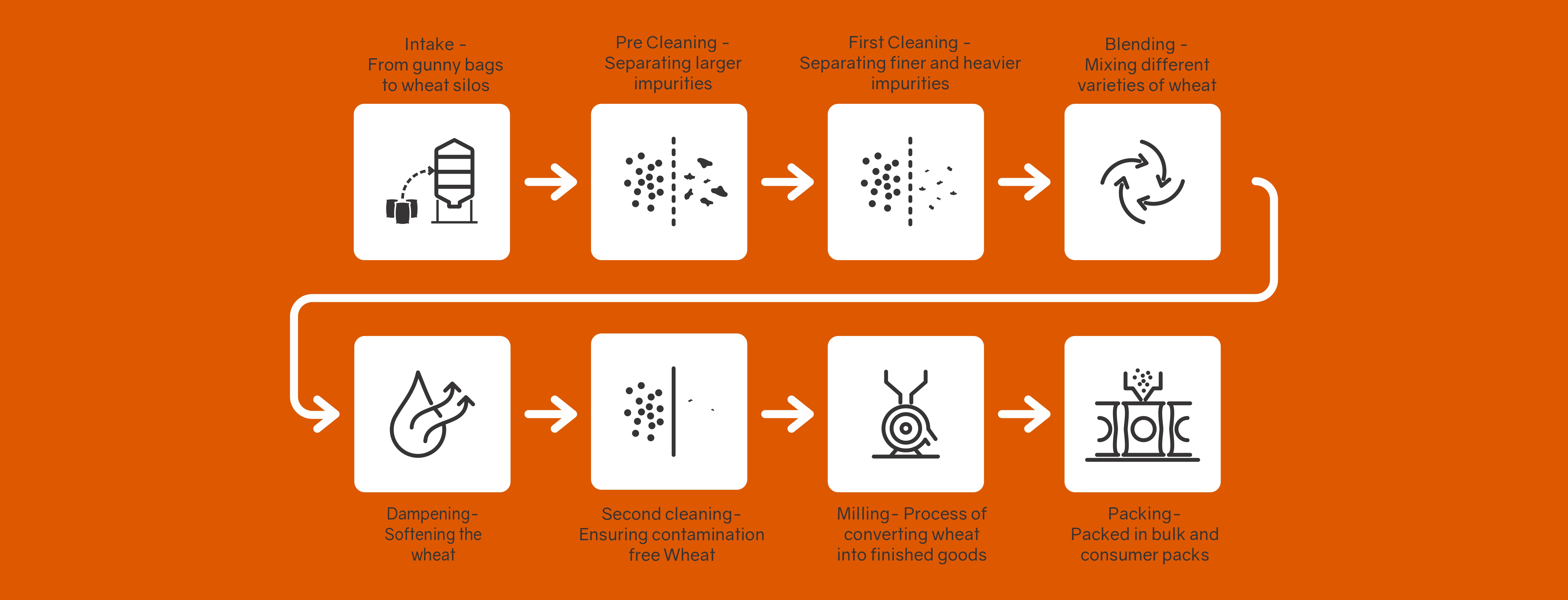

The Best of MP Wheat is procured by highly experienced team at Sanghvi Group, strict quality checks are performed on raw material right at the initial stage to make sure the desired standards are met. These carefully picked grains are stored in food grade galvanized steel silos and raw material warehouses which keeps the wholesome goodness of wheat intact.

At Sanghvi Group, state of art machines from Buhler AG Switzerland are used for intensive cleaning of wheat, which is then processed to make Best quality flour. Traditional chakkis are used to ensure fresh aroma and traditional taste of whole wheat atta. Finished flour is packed through fully automatic machines. The entire process is fully automized without any direct human contact.

There is a 24 hour dedicated lab in all plants with qualified technicians performing checks at every level to ensure Best quality product.